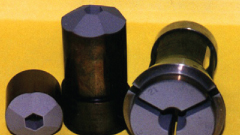

WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

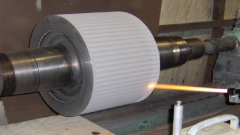

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Generation of High-Quality Plasma Spray Coating

Plasma spray can be a thermal spray coating method made use of to generate a high-quality coating by a mixture of high temperature, higher power heat supply, a comparatively inert spraying medium, usually argon, and high particle velocities. Plasma would be the term used to describe gas that has been raised to such a high temperature that it ionizes and becomes electrically conductive.

The utilization of plasma spray coating technology makes it possible for the spraying of pretty much any metallic or ceramic onto a large range of materials with exceptional bond strength, although minimizing distortion of the substrate.

Plasma Spray Technique

The plasma spray course of action uses a DC electric arc to produce a stream of high-temperature ionized plasma gas, which acts because of the spraying heat supply. The coating material, in powder type, is carried in an inert gas stream into the plasma jet where it really is heated and propelled towards the substrate. Because of the higher temperature and higher thermal power of your plasma jet, components with high melting points are usually sprayed.

The plasma spray gun comprises a copper anode and tungsten carbide, each of which is water-cooled. Plasma gas (argon, nitrogen, hydrogen, helium) flows about the cathode and by way of the anode that is shaped as a constricting nozzle. Plasma spraying produces a high-quality coating by a mixture of a higher temperature, higher energy heat supply, a somewhat inert spraying medium, and very high particle velocities, ordinarily 200-300 m/s.

Plasma spraying has the advantage that it could spray incredibly higher melting point supplies which include refractory metals like tungsten and ceramics like zirconium. Plasma spray coating in all probability accounts for the widest range of thermal spray coatings and applications and makes this procedure one of the most versatile.

Application & Materials Made Use of in Plasma Spray Coating

Thermal Spraying techniques are coating processes in which melted (or heated) supplies are sprayed onto a surface. The “feedstock” or coating precursor is heated by electrical or chemical means. The coating components are fed in powder form, heated to a molten or semi-molten state, and accelerated towards substrates in the kind of micrometer-size particles. Combustion or electrical arc discharge is typically used as the supply of power for energy for thermal spraying. The resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significantly, allowing the coating of flammable substances.

The method of plasma spray coating is widely made use of in the production industries for the development of numerous protective coatings. The coatings applied to mechanical surfaces exhibit pretty higher values of hardness along with enhanced corrosion resistance and abrasion. These properties greatly benefit the working in the machinery and enhancing the lifespan.

Due to its versatility and excellent characteristics the plasma spray coating approach is selected by many technologists as a course of action that offers the widest choice of coating materials. Fretting wear, spraying of tungsten carbide/cobalt seal ring grooves – gas turbines; high-temperature protection, thermal barrier coatings -TBCs onto gas turbine combustion hardware; Wear resistance, spraying of chrome oxide ceramic onto printing rolls for laser engraving; Anti-galling, spraying of molybdenum alloys onto industrial diesel engine piston rings; and Erosion/abrasion resistance, corrosion protection – downhole tool – oil and gas product, and carbides, metallics, ceramics, abradable.