Repair & Rebuild with Coatings

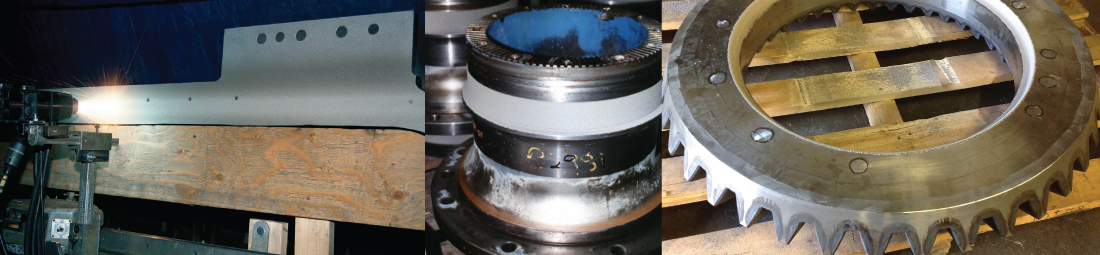

When confronted with the failure of an expensive part, there may be no need to scrap it. At Metallic Bonds we may be able to repair or rebuild the part to a specified size using coatings that can then be machined, milled, ground, finished, or honed.

Coatings can be engineered to combine repair or rebuild with enhanced performance that outlasts the original design many times over. Our coatings do not distort, warp, or crack parts, and do not cause any metallurgical change to the base metal. Repair coatings, which can include steels, carbides, ceramics, alloys, aluminum, and nickel, are applied at thicknesses from .003” to .500”. No curing time is required and parts can be masked to ensure the coating is applied only where it is needed. Shafts, bearings, rollers, gears, and gearboxes made from white and red metals, grey steels, castings, carbides, super alloys, and weldments are all candidates for coating repairs or rebuilds. See our Journal Bearing Repair page for a great example of our repair services. Typical thermal spray processes utilized for repair coatings are HVOF, Plasma, Arc Spray, Flame Spray or Metallizing. Our Brush Plating process is also a good candidate for repairs or rebuilds.

At Metallic Bonds we operate mobile equipment which allows work to be completed quickly at a customer’s site or plant without disassembling the part to be repaired and in some cases, with no further machining needed.

If you are looking for an alternative to scrapping a worn, damaged or mis-machined part, contact us for further information.

Typical Delivery / Turnaround Time is 3 to 5 working days.

24 hour service is available when significant downtime cannot be tolerated.

Product Description

- Repair or rebuild to a specified size

- No need to scrap an expensive part

- Extend part life

Delivery / Turnaround Time

- Typically 3 – 5 working days

- 24 Hour Service Available

Standards Met

- Customer Specifications

Coating Thickness

- .003″ – .500″

Materials

- Carbons steels

- Stainless steels

- Carbides

- Ceramics

- Nickel based alloys

- Aluminum

- Nickel brush plating

Substrates

White Metals

- Aluminum

- Zinc

- Tin

- Titanium

- Babbit

Red Metals

- Bronze

- Brass

- Copper

Grey Steels

- Low carbon steel

- Medium carbon steel

- High carbon steel

- Heat treated steels

- Stainless steels (200,300,400 series)

- Tool steels (D2, M2,H13)

Castings

- Cast iron

- Cast steels

- Ductile iron

Carbides

Super Alloys

- Nickel Based Super Alloys

- Cobalt Based Steels

Other

- Tubing

- Various Welds & Treatments

Industry for Use

- Agricultural

- Grain processing plants

- Cement

- Power plants

- Steel mills

- Mining

- Fracking

- Heavy equipment manufacturing

- Pulverizing

- Conveying

- Automation machinery

- Aluminum mills

- Textile industry

- Abrasive industry

- Fan manufacturing

- Locomotive

- Ship engines

- Lumber mills

- Drywall manufacturing

- Tire manufacturing

- Repair & rebuilders

- Metal working manufacturing

- Gear manufacturing

- Pump manufacturing

- Rotary airlock feeders

- Wire drawing

- Automotive

- Plastics

- Transportation

- Paper

- Printing

- Forging

- Extrusion

- Construction building supplies & tools

- Fabrication

- Tube, pipe and conduit manufacturers

- Tool & die, mold shops

NAVIGATION

ABOUT US

Metallic Bonds, Ltd.

For more than 30 years, Metallic Bonds, Ltd. has been a leader in quality Thermal Spray Coating Services, Brush Plating, and Machine Component Repair.

Toll Free: 1-800-236-3307

Phone: 608-365-9299

1929 Royce Ave

Beloit, Wisconsin 53511

United States

CONTACT US

"*" indicates required fields

© 2024 Metallic Bonds, Ltd. | Blog | Sitemap