Low Coefficient of Friction Coatings

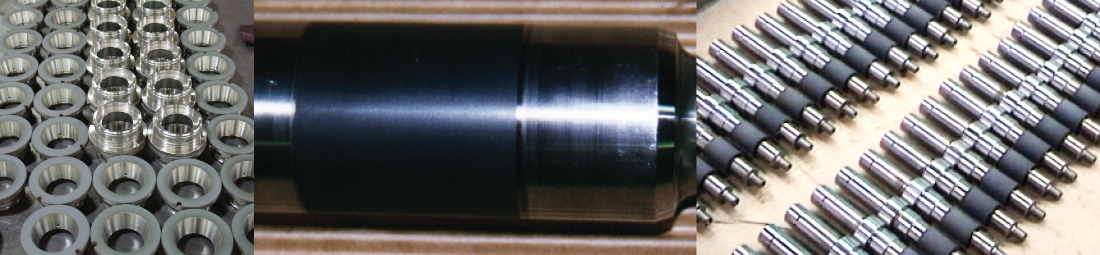

As coating specialists, Metallic Bonds provides a wide range of coatings such as our low coefficient of friction coatings. This high performance coating decreases friction and drag to allow parts and components to function at higher speeds. Faster moving parts and components translate into greater manufacturing output for you, regardless of the application.

Because the coatings include durable materials such as ceramics, carbides, and molybdenum, they serve as replacements for chrome plating and provide a much higher degree of hardness than the base metal. Pump shafts, mechanical seals, and grinder spindles are just a few examples of component parts that can benefit from low coefficient of friction coatings. Our coatings will not distort, warp, crack or render any metallurgical change to base metal. Masking can be utilized to ensure the coating is only applied where specified. Low coefficient of friction coatings, which can be ground to single digit finishes and tight tolerances, function similar to fluoropolymer coatings and are highly resistant to solvents, acids, and other corrosive elements. Typically, the Plasma Spray process is used when applying a low coefficient of friction coating.

We look forward to helping you with your surface technology needs. Contact us for further information.

Typical Delivery / Turnaround Time is 3 to 5 working days.

24 hour service is available when significant downtime cannot be tolerated.

Product Description

- Coated components have the ability to perform at higher speeds

Delivery / Turnaround Time

- Typically 3 – 5 working days

- 24 hour Service Available

Standards Met

- Customer Specifications

Materials

- Ceramic

- Carbides

- Molybdenum

Substrates

White Metals

- Aluminum

- Titanium

- Zinc

- Tin

- Babbit

Red Metals

- Bronze

- Brass

- Copper

Grey Steels

- Low carbon steel

- Medium carbon steel

- High carbon steel

- Heat treated steels

- Stainless steels (200,300,400 series)

- Tool steels (D2, M2,H13)

Castings

- Cast iron

- Cast steels

- Ductile iron

Carbides

Super Alloys

- Nickel Based Super Alloy

- Cobalt Based Steels

Other

- Nickel Based Super Alloy

- Cobalt Based Steels

Industry for Use

- Agricultural

- Grain Processing Plants

- Power Plants

- Steel Mills

- Mining

- Fracking

- Heavy Equipment Manufacturing

- Pulverizing

- Conveying

- Repair & Rebuilders

- Metal Working Manufacturing

- Gear Manufacturing

- Pump Manufacturing

- Rotary Airlock Feeders

- Wire Drawing

- Automotive

- Plastics Industry

- Transportation

- Paper Industry

- Printing Industry

- Chemical plants

- Rubber manufacturing

- Drywall manufacturing

- Tire manufacturing

- Textile industry

- Paper converting

- Forging

- Extrusion

- Construction Building Supplies & Tools

- Fabrication

- Tube, Pipe And Conduit Manufacturers

- Tool & Die, Mold Shops

NAVIGATION

ABOUT US

Metallic Bonds, Ltd.

For more than 30 years, Metallic Bonds, Ltd. has been a leader in quality Thermal Spray Coating Services, Brush Plating, and Machine Component Repair.

Toll Free: 1-800-236-3307

Phone: 608-365-9299

1929 Royce Ave

Beloit, Wisconsin 53511

United States

CONTACT US

"*" indicates required fields

© 2024 Metallic Bonds, Ltd. | Blog | Sitemap