WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

BRUSH PLATING

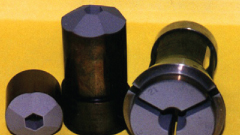

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

The Various Applications of Plasma Spray Coating

The definition of plasma spray coating is a part of a thermal process. The thermal method creates the coating by spraying material in the type of powder into a 14,000 K plasma flame. The material accelerates because of the intense heat and impacts on a substrate material.

When the plasma spray procedure cools, it is named the ‘cold approach.’ After the coating cools, you have an industrial-strength protective coating. It is named the cool method due to the fact any substrate temperature is kept low in the course of the approach, so you do not have any substrate material harm or distortions.

You will discover documented procedures that must be kept anytime you will be implementing the plasma spray coating procedure. There are actually also inspections performed at every single stage of the coating process. The handle panels and powder feeders are closed loops and calibrated as outlined by ISO requirements.

The ISO requirements are precisely calibrated simply because it optimizes the injection of powder into a plasma jet. There’s even testing carried out on sample pieces getting processed. The samples and processes and recorded by lot numbers.

Plasma Spray Coating Method

The plasma spray coating process is complicated, detailed, and heavily regulated. The plasma spray coating approach entails spraying a substrate with molten or semi-molten material to make a tough coating that protects against oxidation and corrosion put on triggered by environmental and operating situations. The coatings are dense and robust, producing plasma coating a favorable option for equipment protection and refinishing.

Plasma spray coatings are applied employing a higher temperature method that entails injecting powdered coating material into a plasma flame. The material is quickly heated after which accelerated toward the substrate. As soon as it reaches the surface it begins to cool, forming a hard coating on the substrate. The higher temperatures involved in plasma coating let the use of ceramics and also other components which have a higher melting point.

Prevalent Plasma Spray Applications

Because of the versatility and fantastic characteristics that plasma spray coatings possess, it really is no wonder that a lot of engineers choose this distinct coating process. Some frequent applications for Plasma Spray coatings are as follows:

Downhole tools from oil and gas production: These parts have to have corrosion protection, wear and erosion resistance

- Marine Applications: Numerous surface ship and submarine components are coated with ceramics to provide resistance to wear, corrosion, and pitting.

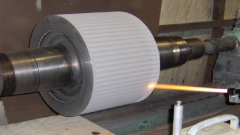

- Printing rolls that are used for laser engraving: Chrome oxide ceramics are sprayed to provide wear resistance and help inside the printing method

- Gas turbine combustion hardware: Thermal barrier coatings are applied to provide high-temperature protection

- Seal ring grooves of gas turbines: Tungsten carbide coatings are made use of to mitigate fretting put on difficulty

This can be just a modest sample of your many applications for Plasma-Sprayed coatings.