WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

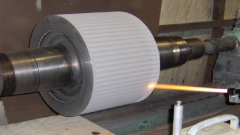

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

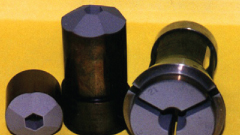

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Nickel-Alloy Coating For Electroless Nickel Plating

The Added Benefits of Electroless Nickel Plating

ENP delivers outstanding corrosion resistance to common corrodents such as saltwater, carbon dioxide, oxygen, and hydrogen sulfide. High phosphorus deposits of ENP (10-14% phos) are also amorphous, which implies that you’ll find no grain or phase boundaries to make initiation websites for corrosion.The uniformity of ENP versus electrolytic deposits is also advantageous, developing a uniformly thick coating across the whole substrate, even in slots, holes, and inside walls of the tubing. Without heat therapy, corrosion-resistant high phosphorus ENP nevertheless delivers excellent hardness and wear resistance properties.ENP offers a cost-effective remedy for applications topic to situations where corrosion is components, extending service life and offering a reduced price alternative to corrosion-resistant alloys, specifically exactly where carbon steel suffers localized corrosion; flange attack or weld corrosion.

Aspects Affecting Electroless Nickel Plating Expenses

The electroless nickel matrix’s cost can differ drastically depending upon the coating’s attributes, required atmospheric protection, hardness/wear qualities, industry situations, element availability, and difficulty of your coating course of action. While the price of a simple electroless nickel phosphorous matrix coating has dropped, the want for many more synergistic specialized matrix coatings has increased the cost of high-end, competitive Components Finishing.In general, working with a bath matrix consisting of a nickel-phosphorous alloy will be the finest method to maintain electroless nickel plating expenses low – assuming this composition tends to make sense for your enterprise and is compatible with the metal components you manufacture or use. A nickel-boron composite tends to lead to the highest electroless nickel plating fees.

It Pays to Check About to Seek Out the Lowest Electroless Nickel Plating Expenses

Electroless nickel plating costs can vary tremendously from one particular plating shop to a different one. If you are thinking about a new/alternate material and finish, team SPC recommends which you view the solution offerings of various Plating shops and inquire, “How a lot really should my coating needs price and what finish is suitable for me?”. Begin initial with our own website totally free quote form.

Do Not Make Your Selection Based on Electroless Nickel Plating Expenses Alone

Even though the cost is certainly an essential factor when picking out a plating organization, it shouldn’t be the only factor. You’ll want to select a company with numerous years of plating experience, particularly in your particular market. The shop must also have the flexibility to create a customized plating resolution that may help achieve your business’s operating targets.