800-236-3307

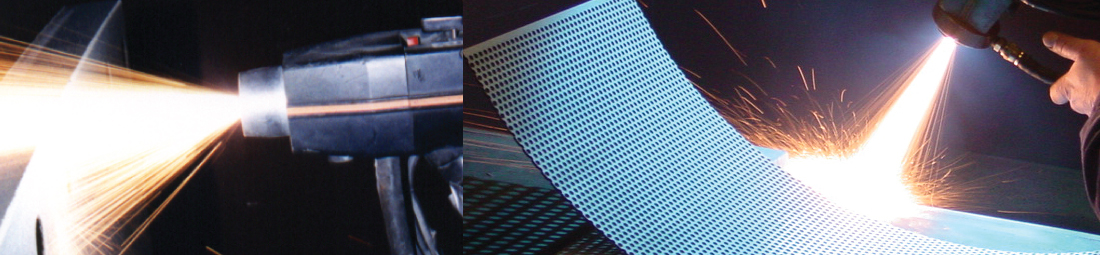

Arc Spray

Two wires are electrically charged in opposite directions. When the wires come in contact with one another, the wires melt. A stream of compressed air then propels the molten particles to a prepared work surface to form a coating. Arc spray coatings are an economical option for restoring parts back to size while providing good wear resistance.

Energy Source & Consumption

Electricity 3-5 kW, Compressed air

2400 Scfh

Spraying Factors

Spray Rates

Deposit Efficiencies

Deposit Per Pass

Particle Velocities

10 to 35 lbs/hour

65% to 75%

.002” to .005”

650 – 800 fps

Coating Properties

Materials

Coating Finishing Processes

Hardness Range of Materials/Coatings

Typical Oxide Content

Typical Porosity Levels

Erosion Resistance Rating

Abrasive Wear Resistance Rating

Thermal Cycling & Thermal Shock Capabilities

Co-efficient of Thermal Expansion & Contraction

Corrosion/Oxidation Resistance Rating

Wire drawn materials, base metals, carbon & stainless steels, some alloy materials

Machine, Mill or Grind

Rc 40-60

5% to 18%

5% to 12%

Fair to Good

Fair to Good

Good

Good

Fair

NAVIGATION

Coating Types

Wear Resistant Coatings

Repair Coatings

Non-Stick/Release Coatings

Thermal Barrier Protection Coatings

Low Coefficient of Friction Coatings

Brush Plating

HVOF

Flame Spray

Metallizing

Nickel Brush Plating

Bearing Shaft Repair Service

Thick Coating Project

General Capabilities

Contact Us

RFQ

ABOUT US

Metallic Bonds, Ltd.

For more than 30 years, Metallic Bonds, Ltd. has been a leader in quality Thermal Spray Coating Services, Brush Plating, and Machine Component Repair.

Toll Free: 1-800-236-3307

Phone: 608-365-9299

1929 Royce Ave

Beloit, Wisconsin 53511

United States

CONTACT US

© 2021 Metallic Bonds, Ltd. | Blog | Sitemap