WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

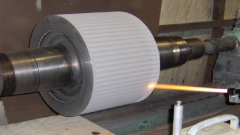

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

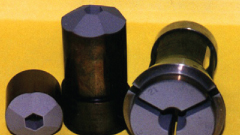

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Exploring the Advantages and Limitations of Thermal Spray Coating

Thermal spray coating is a versatile and widely utilized industrial process crucial in enhancing the performance and longevity of various components and structures. This technique involves applying a protective or functional material layer onto a substrate using a high-temperature heat source. While thermal spray coating offers numerous advantages, it is essential also to consider its limitations to make informed decisions regarding its application. In this article, we will delve into the pros and cons of thermal spray coating and introduce Metallic Bonds LTD as a provider of exceptional thermal spray coating services.

The Pros of Thermal Spray Coating

1. Versatility:

Thermal spray coating is incredibly versatile, making it suitable for various applications. It can apply various materials, including metals, ceramics, polymers, and composites, to different substrates, such as metals, plastics, and ceramics. This versatility allows for customized solutions in industries as diverse as aerospace, automotive, energy, and healthcare.

2. Corrosion Resistance:

One of the primary benefits of thermal spray coating is its exceptional corrosion resistance. Coated components are protected from environmental factors, ensuring a longer lifespan and reduced maintenance costs. This property is precious in offshore, marine, and chemical processing industries.

3. Wear Resistance:

Thermal spray coatings can significantly improve a material’s wear resistance, making it ideal for applications where components are subjected to friction, abrasion, or erosion. This includes turbine blades, automotive engine parts, and industrial machinery.

4. Thermal Insulation:

Certain thermal spray coatings have excellent thermal insulating properties, making them valuable in applications where heat management is essential. This includes heat shields for spacecraft, industrial furnaces, and high-temperature processing equipment.

5. Cost-Effective:

Thermal spray coating is a cost-effective method of extending the lifespan of components and structures. It allows for the refurbishment of worn-out parts rather than replacing them entirely, saving on material and labor costs.

The Disadvantages of Thermal Spray Coating

1. Porosity:

One of the main limitations of thermal spray coating is the potential for porosity in the sprayed layers. This can lead to reduced protective properties and may require additional post-processing steps.

2. Surface Preparation:

To achieve optimal results, proper surface preparation is crucial. Contaminants or roughness on the substrate can negatively impact adhesion and coating quality, necessitating meticulous surface preparation.

3. Limited Thickness:

The thickness of thermal spray coatings is limited, making them less suitable for applications that require very thick or uniform coatings. In such cases, alternative coating methods may be preferred.

4. Line of Sight:

Thermal spray coatings require a direct line of sight between the spray gun and the substrate, limiting their application in complex and intricate geometries.

How Metallic Bonds LTD Can Assist

Metallic Bonds LTD is a leading provider of thermal spray coating services, specializing in applying protective and functional coatings to various substrates. With years of experience in the field, their team of experts ensures the highest quality coatings while addressing the limitations of the process. They offer customized solutions to meet your needs, using state-of-the-art equipment and materials to deliver exceptional results. Whether you require enhanced corrosion resistance, improved wear resistance, or thermal insulation, Metallic Bonds LTD can provide the expertise and capabilities to meet your thermal spray coating requirements.

Thermal spray coating is a valuable industrial process with numerous advantages, including versatility, corrosion resistance, and cost-effectiveness. However, it has limitations, such as porosity and surface preparation requirements. When considering thermal spray coating for your specific needs, you must partner with a trusted provider like Metallic Bonds LTD, known for their expertise and commitment to delivering high-quality coatings tailored to your requirements. By carefully weighing the pros and cons and choosing the right partner, you can maximize thermal spray coating’s potential for your applications.