WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

BRUSH PLATING

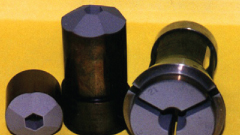

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

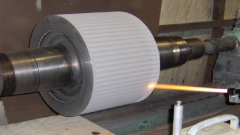

Plasma Spray Coating Surface Arcs

Many industries utilize plasma spray coating to increase the material integrity of their products. The process involves spraying a plasma arc onto a surface and then applying another material on top of that plasma layer. This is an excellent way for many companies to save time and money while creating more durable products!

Though plasma coating is a great way to increase the material integrity of products, it cannot be used on all surfaces. Plasma coating can be used to increase the material integrity of products, but it cannot be applied on all surfaces. Plasma spray coatings are ideal for hard metals like steel and titanium but not so much with softer materials such as aluminum or copper. Though plasma spraying works well in many industries, there are still limitations that companies have to work around in order to maximize efficiency while minimizing costs. The most common application areas include transportation (planes/cars), construction, energy production (wind turbines), etc., That being said – plasma spray coating is often.

Plasma Spray Applications

Plasma spray applications are growing exponentially: plasma spray coatings have been used for decades to protect products and components, but plasma coating technology is still in the early stages of development. As plasma spray applications become more popular with industries worldwide – plasma spray equipment companies are experiencing unprecedented growth!

If you are looking to increase material integrity with plasma coatings or if you want to find out what makes these types of materials so great for many industrial sectors across various markets we highly recommend that you continue reading our post below.

Increase Material Integrity

Plasma coating materials are perfect for increasing material integrity because they actively work to strengthen and protect various products. These plasma coatings aren’t just a protective layer that is quickly burned off, but rather plasma spray coatings bond with the surface of an object creating strength from within! This means you get all the benefits of plasma protection without having to worry about it being chipped or damaged easily. Additionally, plasma sprays can be applied at any angle which makes them ideal for hard-to-reach objects like bolts and nuts on your equipment as well! Plasma sprays also offer many more advantages over traditional solvent-based paints such as better corrosion resistance (up to seven times greater than other types), improved hardness/ durability, better adhesion, and most plasma sprays are environmentally friendly!

These plasma spray coatings can be applied to a variety of different surfaces including metal alloys (steel), stainless steel, aluminum, titanium, copper alloys (bronze), or even ceramics. This means that plasma coating is able to protect parts for your equipment in any environment you may need it to. If you are interested in seeing the ways plasma spray coating can help improve material integrity on your equipment contact us today!