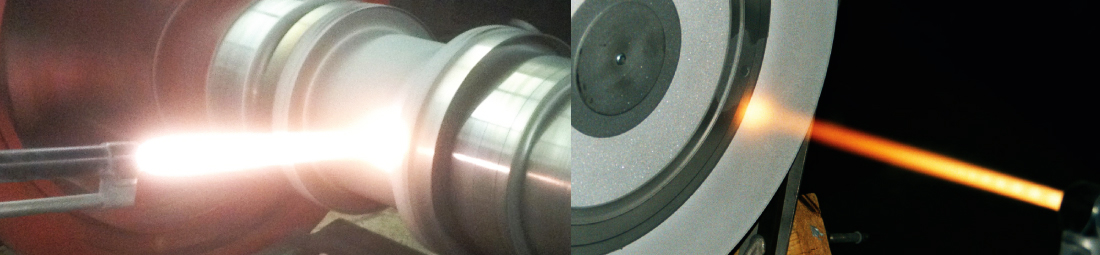

HVOF Coating

High pressure and flows of oxygen and air craft grade fuel gas are ignited and create a high velocity stream. Powder material is injected in the high velocity stream where the material is only partially melted then propels at a high velocity to the prepared work surface. Upon impact, through kinetic energy, the material is then fully melted forming a coating. HVOF coatings are applied in compression instead of containing residual stress. This provides the best wear resistance.

Energy Source & Consumption

Spraying Factors

Oxygen & Fuel Gas, 700 to 2500 Scfh

Spray Rates

Deposit Efficiencies

Deposit Per Pass

Particle Velocities

Oxygen & Fuel Gas, 700 to 2500 Scfh

30% to 50%

.0005” to .001”

3500 to 3900 fps

Spraying Factors

Materials

Coating Finishing Processes

Hardness Range of Materials/Coatings

Typical Oxide Content

Typical Porosity Levels

Erosion Resistance Rating

Abrasive Wear Resistance Rating

Thermal Cycling & Thermal Shock Capabilities

Co-efficient of Thermal Expansion & Contraction

Corrosion/Oxidation Resistance Rating

Tungsten Carbide, Chromium Carbide

Grind

Rc 65-78

Less Than 1%

Less Than 1%

Excellent

Excellent

Fair

Fair to Excellent

Good

NAVIGATION

ABOUT US

Metallic Bonds, Ltd.

For more than 30 years, Metallic Bonds, Ltd. has been a leader in quality Thermal Spray Coating Services, Brush Plating, and Machine Component Repair.

Toll Free: 1-800-236-3307

Phone: 608-365-9299

1929 Royce Ave

Beloit, Wisconsin 53511

United States

CONTACT US

"*" indicates required fields

© 2024 Metallic Bonds, Ltd. | Blog | Sitemap