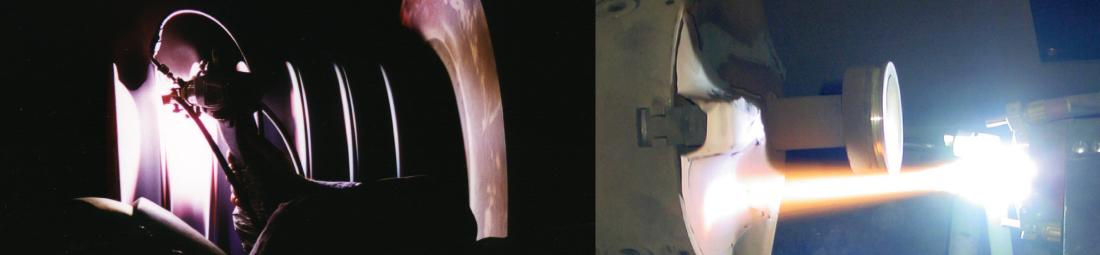

Plasma Spray Coating

An inert gas passes through an arc creating a plasma plume. Powder is injected into the plasma plume, which melts and propels the material onto a prepared work surface to form a coating. The plasma plume reaches temperatures of 15,000° F to more than 30,000° F however, our processing technique ensures the heat does not transfer to the part and will not cause part distortion, warping, cracking, or any changes to the base metals. The plasma process allows for the use of a wide range of coating materials: ceramics, refractory metals, alloy materials and materials containing carbides.

Energy Source & Consumption

Spraying Factors

Electricity 40 kW – 80kW Inert gases 150 scfh

Spray Rates

Deposit Efficiencies

Deposit Per Pass

Particle Velocities

5 to 20 lbs/hour

65%

.0005” to .002”

1200 fps

Coating Properties

Materials

Coating Finishing Processes

Hardness Range of Materials/Coatings

Typical Oxide Content

Typical Porosity Levels

Erosion Resistance Rating

Abrasive Wear Resistance Rating

Thermal Cycling & Thermal Shock Capabilities

Co-efficient of Thermal Expansion & Contraction

Corrosion/Oxidation Resistance Rating

Ceramics, Refractory Metals, Alloy Materials (Containing Carbides)

Machine, Mill or Grind

Rc 62-75

2% to 5%

2% to 5%

Good

Good

Excellent

Excellent

Excellent

NAVIGATION

ABOUT US

Metallic Bonds, Ltd.

For more than 30 years, Metallic Bonds, Ltd. has been a leader in quality Thermal Spray Coating Services, Brush Plating, and Machine Component Repair.

Toll Free: 1-800-236-3307

Phone: 608-365-9299

1929 Royce Ave

Beloit, Wisconsin 53511

United States

CONTACT US

"*" indicates required fields