WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

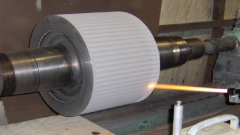

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

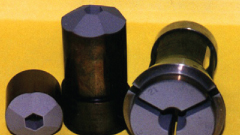

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

The Importance of Electroless Nickel Plating in Modern Manufacturing

In today’s competitive manufacturing landscape, precision, durability, and corrosion resistance are non-negotiable. Industries ranging from aerospace and automotive to electronics and heavy machinery rely on specialized coating techniques to enhance the performance and longevity of components. Among these methods, electroless nickel plating (ENP) stands out as a highly effective, cost-efficient, and versatile surface treatment.

What Is Electroless Nickel Plating?

Electroless nickel plating is a chemical process that deposits a uniform layer of nickel-phosphorus alloy on a substrate without the use of electrical current. Unlike electroplating, which requires electricity and line-of-sight accessibility, ENP uniformly coats complex geometries and internal surfaces, making it ideal for intricate components.

Key Advantages of Electroless Nickel Plating

- Uniform Thickness and Coverage. One of the biggest advantages of ENP is its ability to produce an even coating across the entire surface of a part, including deep recesses, threads, and complex shapes. This uniformity ensures consistent protection and performance.

- Enhanced Corrosion Resistance. The phosphorus content in the nickel alloy provides excellent resistance to corrosion, especially in harsh environments. This makes ENP highly suitable for applications involving exposure to chemicals, saltwater, or high humidity.

- Improved Hardness and Wear Resistance. Electroless nickel plating significantly increases surface hardness. When heat-treated, the coating can reach hardness levels comparable to hard chrome, making it effective in extending the lifespan of machine components subject to wear and abrasion.

- Superior Lubricity. The smooth, low-friction surface created by ENP enhances the performance of moving parts and reduces the need for additional lubricants, contributing to more efficient operation and reduced maintenance.

- Cost Efficiency. The consistent and predictable nature of the ENP process reduces the need for costly rework or secondary machining. It also minimizes downtime due to improved wear life and maintenance intervals.

- Excellent Adhesion. Electroless nickel adheres well to a wide range of substrates, including steel, aluminum, copper, and even non-metallic materials like plastics, broadening its applicability across diverse industries.

ENP in Real-World Manufacturing

In sectors like aerospace, ENP is used to protect landing gear components and hydraulic systems. In the automotive industry, it’s applied to fuel system parts and engine components. Even in electronics, ENP provides a solderable surface for connectors and circuit boards.

Metallic Bonds, Ltd. — Your Surface Engineering Partner

As a leader in thermal spray coating services, brush plating, and machine component repair, Metallic Bonds, Ltd. recognizes the value of advanced surface treatment processes like electroless nickel plating. Their commitment to precision and quality ensures that every component they restore or enhance meets the highest standards of durability and performance.

Whether you’re looking to extend the service life of critical equipment or enhance corrosion protection, Metallic Bonds, Ltd. delivers tailored solutions to meet the evolving demands of modern manufacturing.