WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

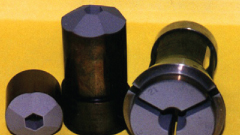

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Understanding the Ceramic Coating Process: Advantages and Disadvantages

When it comes to enhancing the performance, durability, and longevity of industrial components, ceramic coatings stand out as one of the most reliable and efficient solutions. From aerospace to automotive, manufacturing to energy production, ceramic coatings offer impressive protection against wear, corrosion, and extreme temperatures.

At Metallic Bonds, Ltd., we specialize in high-performance Thermal Spray Coating Services, including ceramic coatings, as well as Brush Plating and Machine Component Repair. With decades of experience and a reputation for precision and quality, we help businesses across industries get the most from their machinery and parts.

What Is the Ceramic Coating Process?

Ceramic coating involves the application of a non-metallic, inorganic material—typically an oxide, carbide, or nitride—onto a metal surface to provide a protective layer. One of the most common methods of applying ceramic coatings is through thermal spray technology.

Here’s a general overview of the ceramic coating process:

- Surface Preparation

The base surface is cleaned and roughened—often using abrasive blasting—to ensure strong adhesion of the coating. - Material Selection

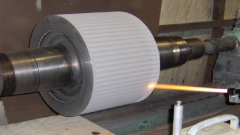

The type of ceramic material used depends on the application. Common options include aluminum oxide, zirconium oxide, and chromium oxide. - Thermal Spray Application

The ceramic material, in powder or wire form, is melted using a high-temperature source (like a plasma or flame spray) and then sprayed onto the prepared surface. This results in a dense, bonded coating that adheres firmly to the substrate. - Curing and Finishing

Some coatings may require post-treatment, such as curing or polishing, to meet performance specifications.

Advantages of Ceramic Coatings

- Exceptional Heat Resistance

Ideal for applications involving high temperatures, ceramic coatings can withstand up to 2000°F or more. - Wear and Abrasion Resistance

The hardness of ceramic materials helps protect against mechanical wear and surface damage. - Corrosion Protection

Ceramic coatings offer a strong barrier against moisture, chemicals, and oxidation. - Thermal Barrier Protection

They reduce heat transfer, which helps protect internal components in engines and turbines. - Electrical Insulation

Many ceramic coatings have excellent dielectric properties, useful in electrical and electronic applications. - Extended Component Lifespan

By protecting against multiple failure modes, ceramic coatings help reduce downtime and maintenance costs.

Disadvantages of Ceramic Coatings

- Brittleness

Ceramic coatings can be more brittle than metallic coatings, making them vulnerable to cracking under high mechanical stress or impact. - Higher Initial Cost

The application process, materials, and equipment can be more expensive compared to conventional coatings. - Application Complexity

The process requires specialized equipment and trained professionals to ensure quality and consistency. - Limited Flexibility

Ceramic coatings may not perform well in applications that involve heavy vibration or flexing, as they may delaminate over time.

Why Choose Metallic Bonds, Ltd.?

With a strong track record of success in Thermal Spray Coating Services, Brush Plating, and Machine Component Repair, Metallic Bonds, Ltd. brings unmatched technical expertise and customer-focused service to every project. Whether you need to restore worn components or protect high-performance equipment, our ceramic coating solutions are engineered for precision, performance, and longevity.

Need expert ceramic coating services? Contact Metallic Bonds, Ltd. today to learn how our advanced surface technologies can enhance your operation’s reliability and efficiency.