WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

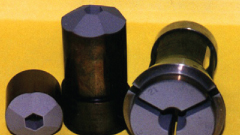

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Understanding the Ceramic Coating Process: Benefits and Applications

In industrial settings where machinery, tools, and components are constantly exposed to harsh environments, finding durable, protective surface treatments is crucial. One such solution is ceramic coating—a process that enhances the performance and longevity of metal surfaces.

What Is Ceramic Coating?

Ceramic coating is the application of a non-metallic, ceramic-based material onto a metal surface to improve its thermal resistance, wear protection, and chemical stability. Unlike paint or conventional plating, ceramic coatings form a high-hardness barrier that bonds physically and chemically with the substrate.

There are several application methods, including:

- Thermal spray coating (plasma, flame, HVOF)

- Chemical vapor deposition (CVD)

- Physical vapor deposition (PVD)

- Sol-gel and dip coating techniques

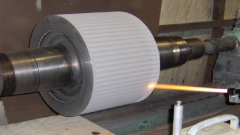

The Ceramic Coating Process

- Surface Preparation

The base material must be thoroughly cleaned and prepared, usually through grit blasting or degreasing, to ensure maximum adhesion. Removing rust, oils, and oxidation is critical. - Coating Application

A ceramic material—such as aluminum oxide, chromium oxide, or zirconium oxide—is heated to a molten or semi-molten state and propelled onto the prepared surface using thermal spray equipment. - Bonding and Layer Formation

Upon contact, the ceramic particles rapidly cool and solidify, forming a dense, tightly bonded coating. Depending on the desired thickness and function, multiple passes may be applied. - Post-Coating Treatments

Final steps may include grinding, polishing, or sealing the coating to improve smoothness, appearance, and additional resistance properties.

Benefits of Ceramic Coating

Ceramic coatings offer numerous advantages across industrial, automotive, aerospace, and marine sectors. Here are some key benefits:

- Exceptional Wear Resistance

Ceramic coatings provide a hard, abrasion-resistant surface that protects machinery components from wear and tear. This is especially critical in manufacturing environments with high friction and movement.

- Superior Corrosion Protection

By creating an impermeable barrier, ceramic coatings guard against corrosion from water, chemicals, and oxidation. This benefit is ideal for parts exposed to saltwater, industrial chemicals, or humid conditions.

- High Thermal Stability

Ceramic coatings can withstand extreme temperatures—some over 1000°C—without degradation. They are often used in applications involving exhaust systems, turbines, and foundry equipment.

- Chemical Resistance

Resistant to acids, alkalis, and solvents, ceramic coatings protect equipment in chemical processing plants and other corrosive environments.

- Extended Component Lifespan

By minimizing surface damage and corrosion, ceramic coatings dramatically extend the life of components—reducing downtime, maintenance, and replacement costs.

- Improved Performance

Ceramic-coated surfaces often operate more efficiently due to reduced friction and heat buildup, which enhances machine performance and energy savings.

Applications of Ceramic Coating

- Turbine blades and engine components in aerospace and power generation

- Industrial rollers, pumps, and shafts are subject to abrasive conditions

- Automotive exhaust headers and pistons for heat and wear resistance

- Food and chemical processing equipment needs chemical inertness

- Oil and gas drilling tools operating in high-pressure, corrosive environments

Trust the Experts at Metallic Bonds, Ltd.

With decades of experience in thermal spray coating, brush plating, and precision machine component repair, Metallic Bonds, Ltd. has the expertise to recommend and apply the right ceramic coating for your specific needs. Our coatings are engineered for durability, efficiency, and long-term value—helping you keep your equipment running at peak performance under the most demanding conditions.

Ready to enhance your equipment with advanced ceramic coatings?

Contact Metallic Bonds, Ltd. today to learn how our industrial coating solutions can extend your machinery’s life and performance.