WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

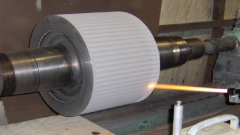

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

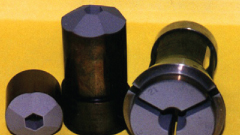

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Understanding the Electroless Nickel Plating Process: Advantages and Disadvantages

Electroless nickel plating is a highly effective metal finishing process that deposits a uniform layer of nickel-phosphorus or nickel-boron alloy onto a substrate without the use of electrical current. Unlike traditional electroplating methods, electroless plating relies on a controlled chemical reaction between a reducing agent and nickel ions in a solution to achieve consistent and even coverage over the entire surface, including complex geometries, recessed areas, and internal surfaces.

The Electroless Nickel Plating Process: Step-by-Step

- Surface Preparation

Proper surface preparation is crucial for successful plating. The component is thoroughly cleaned and degreased to remove any dirt, oils, or oxidation. This may involve abrasive cleaning, acid etching, or chemical treatment. - Activation

The surface is then activated, typically through a pre-treatment that promotes the adhesion of the nickel layer to the substrate. This may include zincating for aluminum or other specialized procedures, depending on the base material. - Immersion in Plating Bath

The cleaned and activated part is submerged in a specially formulated solution containing nickel salts and a reducing agent such as sodium hypophosphite. The reducing agent triggers the deposition of nickel onto the surface without the need for an external power source. - Controlled Deposition

As long as the part remains immersed, nickel continues to be deposited uniformly. The thickness can be controlled by adjusting the plating time and bath parameters. - Rinsing and Finishing

After achieving the desired thickness, the component is rinsed and dried. Additional heat treatment may be applied to enhance hardness and improve wear resistance.

Advantages of Electroless Nickel Plating

- Uniform Coating

One of the biggest advantages is its ability to deposit an even layer on intricate shapes and hard-to-reach areas, unlike electroplating, which can lead to uneven thickness. - Superior Corrosion Resistance

The nickel-phosphorus alloy offers excellent protection against oxidation and corrosion, especially in marine and chemical environments. - Improved Wear Resistance

Heat-treated electroless nickel coatings can be tough and resistant to abrasion, making them ideal for high-friction applications. - Non-Conductive Substrates

Electroless plating can be used on non-conductive surfaces when pre-treated, allowing for broader material compatibility. - Reduced Porosity

The plating tends to be less porous than electroplated coatings, offering a better barrier to corrosive agents.

Disadvantages of Electroless Nickel Plating

- Higher Operating Costs

The chemicals involved and the careful monitoring required for bath stability can make the process more expensive than conventional electroplating. - Slower Deposition Rate

Compared to electroplating, the rate at which the nickel is deposited is slower, which can increase production time for thicker coatings. - Bath Maintenance

The chemical bath needs frequent analysis and control to maintain effectiveness, requiring technical expertise and proper waste management. - Limited Bath Life

The plating bath degrades over time and must be replaced, contributing to operational downtime and disposal challenges.

Applications of Electroless Nickel Plating

Electroless nickel plating is widely used across multiple industries, including:

- Aerospace and Automotive: Engine parts, fuel systems, and turbine components

- Electronics: Connectors, circuit boards, and housings

- Oil & Gas: Pump components, valves, and tools exposed to harsh environments

- Manufacturing: Gears, shafts, and precision machine parts

Partner with the Experts: Metallic Bonds, Ltd.

With decades of industry experience, Metallic Bonds, Ltd. stands out for delivering exceptional thermal spray coating services, brush plating, and machine component repair. Their proficiency in electroless nickel plating ensures that your components receive durable, uniform, and high-performance coatings tailored to withstand the rigors of industrial use.

If you’re seeking consistent protection, extended component life, and professional service, Metallic Bonds, Ltd. is your trusted partner in advanced surface technologies.