WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

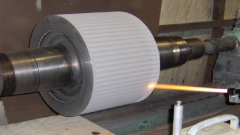

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

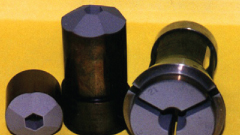

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

Understanding Thermal Barrier Protection: Enhancing Performance and Longevity

In today’s high-performance industrial environments, managing heat is more critical than ever. Excessive temperatures can degrade components, reduce efficiency, and shorten the life span of equipment. One proven solution to combat these challenges is thermal barrier protection—a specialized technology designed to insulate components from extreme heat while preserving their structural integrity.

What Is Thermal Barrier Protection?

Thermal barrier protection (TBP) refers to a range of materials and coating techniques applied to surfaces to shield them from high-temperature environments. These protective layers significantly reduce the heat transfer to the substrate material, maintaining lower operational temperatures and preventing thermal degradation.

The most common method of delivering this protection is through thermal spray coatings, which involve the application of heat-resistant materials such as ceramics, metal alloys, or composites onto a component surface using high-velocity spraying equipment.

Key Benefits of Thermal Barrier Protection

- Heat Insulation and Energy Efficiency

By reducing the amount of heat transferred to engine or machinery components, TBP coatings help maintain thermal efficiency and reduce the energy required to keep systems cool. This is especially critical in gas turbines, automotive engines, and industrial furnaces.

- Extended Component Life

Thermal barrier coatings act as a shield against oxidation, corrosion, and thermal fatigue. This can greatly extend the service life of components exposed to harsh conditions—saving time and money on replacements and repairs.

- Improved Performance in High-Temperature Environments

High-performance systems often operate at the edge of thermal limits. TBP allows them to run hotter, longer, and more reliably without compromising material integrity.

- Reduced Maintenance Costs

By minimizing thermal damage, components treated with thermal barrier protection require fewer interventions, inspections, and replacements—ultimately reducing downtime and maintenance expenses.

Common Applications of Thermal Barrier Coatings

Thermal barrier protection is widely used in industries where high temperatures are common. Typical applications include:

- Aerospace – Jet engine turbine blades and combustion chambers

- Automotive – Cylinder heads, exhaust systems, and pistons

- Power Generation – Gas turbines, boilers, and heat exchangers

- Manufacturing – Die casting molds, furnace linings, and extrusion equipment

Thermal barrier protection is more than just a coating—it’s a critical investment in the longevity, reliability, and efficiency of high-performance systems. Whether you’re looking to improve component durability or push your equipment to its thermal limits, Metallic Bonds, Ltd. has the expertise and technology to deliver superior results.

Contact us today to learn more about how our thermal barrier solutions can protect your most valuable assets from the damaging effects of heat.