WEAR RESISTANT COATINGS

PROTECT AGAINST ABRASION, EROSION, CORROSION, FRETTING/GALLING, CAVITATION, BRINELLING.

REPAIR COATINGS

NO NEED TO SCRAP AN EXPENSIVE PART. REPAIR OR BUILD UP TO A SPECIFIED SIZE. EXTEND PART LIFE.

RELEASE COATINGS

FEATURING DURA-SLIK™ FLUOROPOLYMER COMBINED WITH THERMAL SPRAYED COATING PROVIDES WEAR RESISTANCE ALONG WITH RELEASE PROPERTIES.

THERMAL BARRIER PROTECTION COATINGS

RESISTS TEMPERATURES UP TO 3000° F. ALLOWS THE USE OF LESS EXPENSIVE SUBSTRATE.

LOW COEFFICIENTOF FRICTION COATINGS

COATED COMPONENTS HAVE THE ABILITY TO PERFORM AT HIGHER SPEEDS.

SURFACE TRACTION COATINGS

Long lasting surface finishes that prevent slippage, interruptions & breaks. Improves web tracking and tension control.

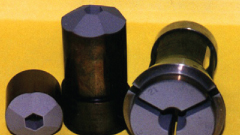

BRUSH PLATING

Repair or rebuild to a specified size, tolerance and surface finish. Plate an entire surface or target a small localized area.

GENERAL CAPABILITIES

Services, coating features, part size capability.

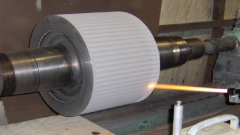

Plasma Spray Coating to Soften Metal

Plasma spray coating may be the most flexible method out of all the thermal spray processes. Generally, it can be the spraying of molten or heat-softened material onto a surface to provide a coating. The utilization of effective plasma spray coating technologies can facilitate the spraying of almost any ceramic, cermet, or metal onto a wide selection of supplies with exceptional bond strength at the same time as a minimal distortion in the substrate.

Plasma Spray Coating Process

Plasma Spray Course of action entails spraying semi-molten material onto a substrate surface to supply a functional coating. The material in powder form is injected into a very higher temperature plasma spray flame, exactly where it really is rapidly heated and accelerated to a high velocity. The hot material impacts around the substrate surface and swiftly cools to type the coating. This procedure is sometimes known as a cold course of action (relative to the substrate material) since the plasma sprayed substrate temperature might be kept low in the course of processing, therefore, avoiding harm. The Plasma Spray Procedure might help prevent undesirable metallurgical modifications and distortion to the substrate material.

The objective of plasma spray coating is always to heat up and scatter material particles across the function surface with minimum waste and overspray. Prior to the HVOF technique was invented, plasma guns were widely applied for adding velocity towards the material particles. Plasma arc, as the gun is named, was devised as an electrical appliance that could efficiently replace the old flame spray machines. These guns can heat up the particulates to a specific degree to ensure that they will effortlessly be deformed to be applied around the function surface. By connecting the poles of an energy supply unit to an electrode and concentric nozzle, a plasma arc is usually created. A high flow-rate inert gas (either the combination of nitrogen & hydrogen or the mixture of argon & hydrogen or helium) along the arc’s axis is often added to push the arc forward towards the front on the plasma gun.

Next, we inject the powder (made from metals, ceramics, or cermets) into the flaming plasma near the nozzle. The gas and powder arc expands quickly and the resultant velocity pushes the hot powder particles forward. Under higher velocity, these molten components are propelled onto a substrate, causing a high integrity coating with excellent bonding. The entire approach of thermal spaying is also cleaner, more efficient, and safer than ever prior to the courtesy of technological advancements. As thermal spray, plasma spray, and other techniques and materials continue to improve, so do the characteristics of the parts and surfaces upon which they are sprayed.

The Pros

Can produce a wide range of coating components (in powder type) to meet a wide range of needs. Compared to other traditional thermal processes like flame spraying, plasma spray coatings are of higher quality.

The Cons

Plasma spraying requires automated gun manipulators. Manual operation is deemed as unsuitable. Also, coating restricted access surfaces and small-diameter internal bores is challenging as it is actually a line-of-sight procedure.